About us

LYNX GmbH

Our world is the finishing

We offer

- Laminators

- Flatbed laminators

- Solutions for automated cutting

- Destacking or placement automation

- Devices for fast welding of foils

- Sublimation calender

- Sheet metal cutting machines

- Solutions for cutting and slitting films, technical adhesive tapes and flexible materials of all kinds

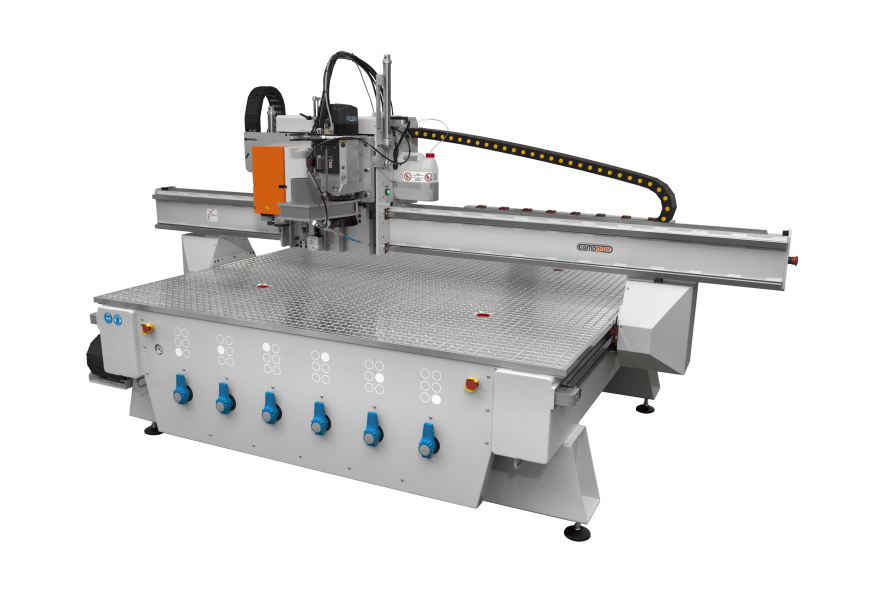

- CNC milling machines

- Digital flatbed plotters

DTF supplier

We have also established ourselves as a provider of DTF (direct-to-film) solutions. We supply various DTF printers with drying ovens and integrated adhesive application.

A DTF print is only as good as the materials used, which is why we supply all consumables such as: DTF ink, DTF hotpeel/coldpeel and various DTF adhesives for every type of application - and most of it is "Made in Europe"!

Our newest area is industrial flatbed and cutting solutions as well as CNC milling machines for all industries that want to cut or mill materials.

Together with our partners,

we create the perfect solutions

The Italian machine manufacturer Flexa has been our partner for more than 12 years. Since 1993, Flexa has specialized in the development of systems for enhancing and upgrading large-format digital prints.

The range comprises more than 200 products for print service providers, industry and advertising technology. These include laminators, industrial laminators, sublimation calenders, automatic XY sheeters, slitters, welding systems for banners and tarpaulins, rewinders and unwinders, roll holders and various special solutions. 10,000 machines sold speak for the success and quality of the machines.

Solutions for your applications

- Large-format signs, PVC billboards, illuminated signs and neon signs

- Advertising displays, illuminated displays, roll-ups, banners

- Corporate safety and workplace signage

- Lamination in the glass industry

- Lamination in the printed circuit board industry

- Tags and labels with 3D doming effect

- Wallpaper printing

- Displays made of Plexiglas and acrylic glass

- Fabric printing

- Custom-made products / special designs

COMAGRAV

Another market leader in its segment is our newest partner, COMAGRAV. Comagrav is a manufacturer of professional flatbed plotters, multifunctional CNC routers and digital plotters. COMAC spol. s.r.o. from the Czech Republic has been developing and manufacturing cutting, routing and engraving solutions for almost all materials, whether wood, metal or hard and foam materials, since 1999.

Comagrav machines are used successfully worldwide in various sectors, including advertising technology, display production and the packaging industry. Special solutions are an important part of the program thanks to many years of experience and our own development team.

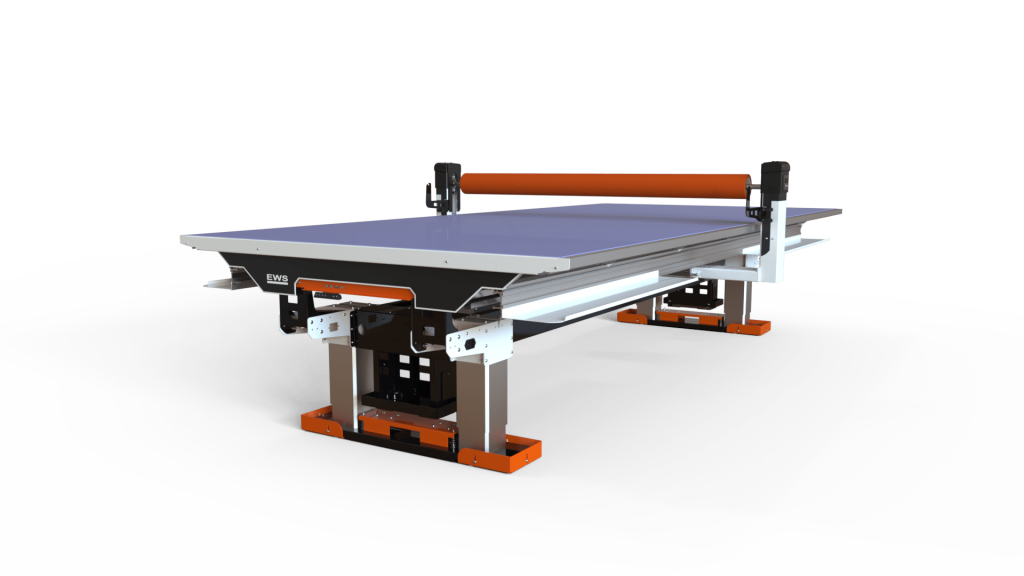

Moditech

With the "EWS" work and laminating station from Swedish manufacturer Moditech Scandinavia, Lynx Germany now also offers desktop laminators for further processing. Patrik Johansson and Alexander Johansson are the passionate technical team behind the practical and clever work and laminating station.

Patrik is one of the world's most experienced designers and inventors of flatbed laminators, who also founded the two well-known brands Rolls Roller and CWT. Moditech flatbed laminators have 4 generations of these machines as experience.

SIGNHACKS

SIGNHACKS solutions for your applications

Weeding

Ergonomic working with film

Use of application tape

DTF Direct to Fabric

Produce textile transfers digitally in any color - and cost-effectively from a print run of 1! With this new technology, you can produce transfers for your textile customers and are not limited in the quantity or creativity of the motif. With the DTF Speedline, the Transfer Jet and the DTF Compact series, we offer a total of three different systems in up to 10 configurations! This means that we have the optimum solution for every application!

These solutions offer a highly competitive technology compared to flex transfers, screen printing and DTG (direct-to-garment) printing. The products are Ökotex-certified.

- 3-in-1 system: print - transfer powder - fix

- Short production time

- Feels very thin and is extremely stretchy

- No more contour cutting and weeding!

- No pre- and post-treatment process as with DTG (Direct to Garment)

- Environmentally friendly process with water-based textile pigment inks and PU transfer adhesive

- Suitable for transfer to most textiles (cotton, polyester, ...), both dark, colored and white textiles

- Excellent wash resistance: In the test. We expect at least 40 washes at 40ºC. Also good results at 60ºC

- Suitable for T-shirts, pants, vests, shoes, workwear, ... etc.

- Suitable for transferring to hard surfaces such as wood, metal, acrylic, ...etc.

Partnerships for the customer experience

As none of this works without good workflow software, we work closely with Printfactory, the market leader in workflow, color management and RIP software.

With PrintFactory, we can realize the dream of networked production at several locations, if desired and sensible, from prepress to postpress!

But the strength of this complete RIP solution is also evident when controlling just one printer.