Industrial Laminators

We are your partner when it comes to advice and service when it comes to laminating flexible and rigid media. Hot or cold laminating in all industries and trades, whether in digital printing, screen printing, advertising technology or the glass industry – we have the solution!

MILLENNIUM INDUSTRIAL

Designed for Hot and Cold Lamination of Flexible Materials

Industrial laminating machine designed for hot and cold bonding of flexible materials, lamination, application of tape and double-sided adhesive, assembly and encapsulation.

Applications

- Touch screen

- Unwinding and winding shaft

- Orientation of the roles

- Cutting unit

- Rear casters

- Rear worktop with feed guide

- Guided reference square for hard materials

- Connector for the connection of the cutting machine and the winding device

- Control of loading by hand (control panel) or foot pedal (hands-free operation)

- Easy coil loading and unloading

MILLENNIUM INDUSTRIAL

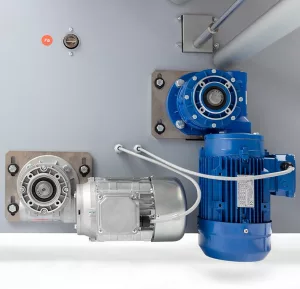

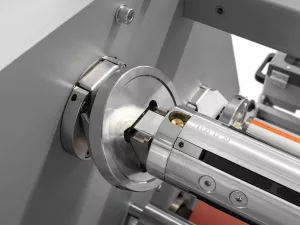

Industrial laminator for connecting sheet steel and silicone film by vulcanization.

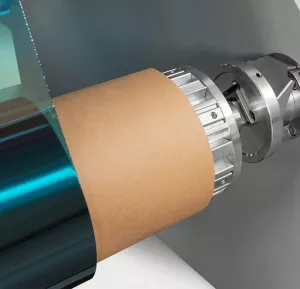

It combines different types of roll insulation materials such as polyester, polyamide, teflon, etc. It is suitable for working with large rolls up to 350mm in diameter and weighing up to 150kg and is equipped with 6 shafts with adjustable tension.

Applications

- Touch screen

- Rear drive rollers with pneumatic lift and manual controls

- Precise tension adjustment with pneumatic brakes and load cell

- Two pneumatic units for edge trimming

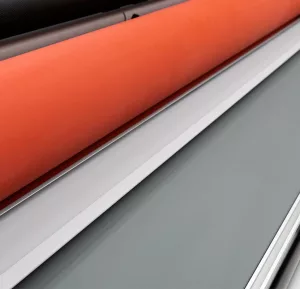

- Easy loading of the rolls thanks to the air expansion shaft (3″ or 6″)

- Rolls with a diameter of up to 350 mm and a weight of up to 150 kg

- Sheet steel/silicone/polyester/teflon

- Polyamide / Double-sided adhesive

MILLENNIUM INDUSTRIAL

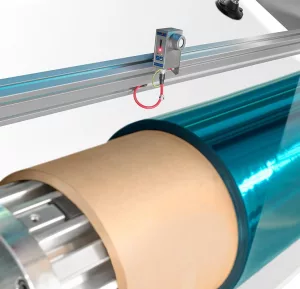

Industrial laminator for light-sensitive films for windows in residential and commercial areas

The coupled film creates a natural barrier against the sun’s UV rays. It is suitable for working with large rolls up to 400mm in diameter and weight up to 250kg and is equipped with 6 shafts with adjustable tension.

Applications

- Touchscreen display with pivoting arm for maximum ease of use

- Rear drive rollers with pneumatic lift and manual controls

- Precise tension adjustment with pneumatic brakes and load cell

- Two pneumatic units for edge trimming

- Easy loading of the rolls thanks to the air expansion shaft (3″ or 6″)

- For many foils and self-adhesive foils with or without carrier material

GLASS 170

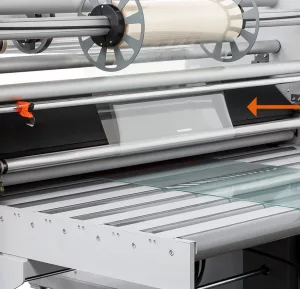

Compact Roll Laminator

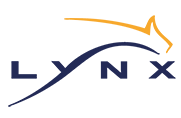

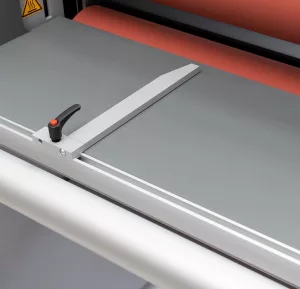

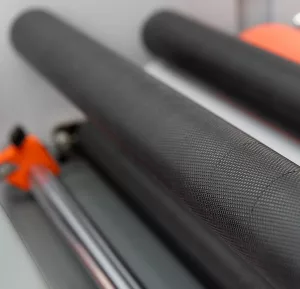

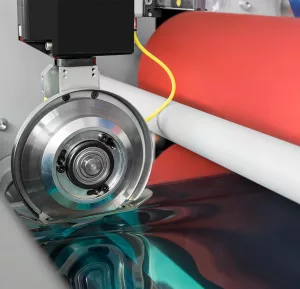

Professional laminator for applying pressure-sensitive films to rigid substrates (glass, wood, steel, etc.). Equipped with an integrated contact cleaning system and an anti-dust bar to remove dust from the surface before it is laminated with foil.

Applications

- Contact cleaning system of the substrate to be laminated with antistatic bar to remove dust on the surface

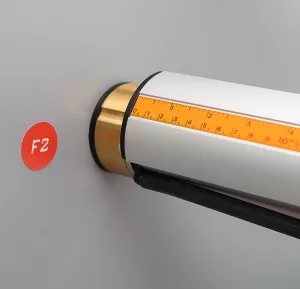

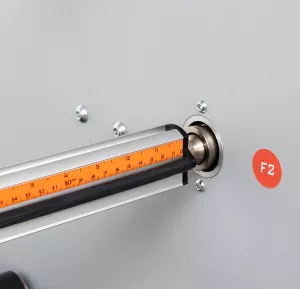

- It maintains the same tension regardless of the roll diameter

- Cleaning system roller pressure indicator

- Cutting device for trimming the film if it is wider than the panel

- Laterally adjustable reference bar for correct positioning of the substrate to be laminated

- Sensor for stopping the advance of the panel on the outfeed roller table

- Manual lifting of the upper lamination cleaning roller and the lamination roller (motorization optional)

- Rigid substrate feed control via keyboard or foot pedal

- Antistatic winding dust protection between cleaning and laminating roller

- Anti-crushing photosensitive device and emergency push-buttons

Service

Service/maintenance/repair/sale of almost all laminators.

Seal Laminators

Seal 62 Base/Seal 62 Pro S/ SEAL 62 PRO D/ Seal Pro Series

Neschen Laminators

ColdLam 1650/HotLam 1650 TH/ HotLam 1650 DoubleH/ EcoLam 1650

Kala Laminators

Kala Mistral Pro/ Kala Arkane/ Kala Starter

Biedermann laminators

Biedermann RollLam

Dataplot

Emblem Easylam Laminator